Xu Peng's work has been accepted by Electrochimica Acta.

Pitting mechanism in a stainless steel-reinforced Fe-based amorphous coating

Abstract

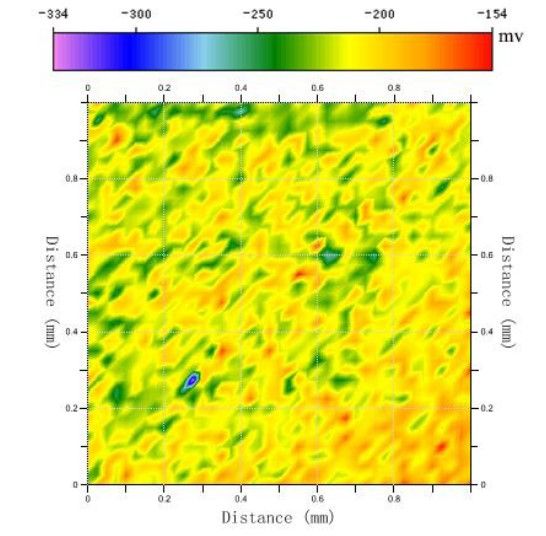

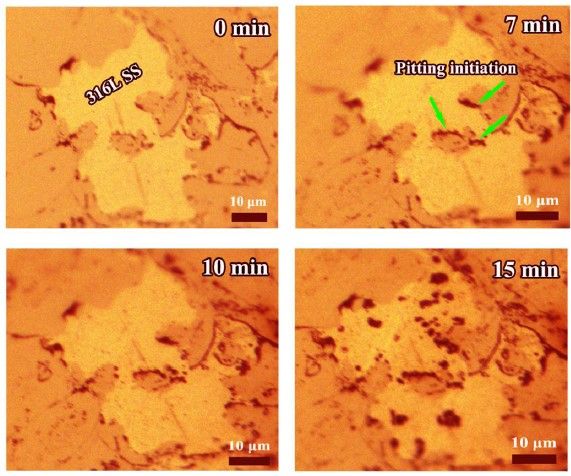

There is keen interest in developing Fe-based amorphous composite coatings with superior bonding strength and mechanical properties for load-bearing applications. However, the corrosion resistance of these composite coatings decreases in harsh Cl− solutions; the interfaces between the added second phase and the amorphous matrix always suffer from pitting corrosion. The underlying pitting mechanism has remained elusive, delaying progress in this field. In this study, the pits initiation behaviour of a Fe-based amorphous coating reinforced with stainless steel powder is systematically investigated in a 3.5% NaCl solution through polarization, electrochemical noise, scanning kelvin probe and ‘in situ observation’ measurements, as well as high-resolution transmission electron microscopy. The pitting resistance was found to deteriorate obviously when stainless steel phase is added to the amorphous coating. The results indicate that pitting at the interfaces is not caused, as generally believed, by microgalvanic corrosion between the stainless steel phase and the amorphous matrix. Instead, it is caused by Fe3O4 oxide formation at the interfaces due to the strong tendency towards oxidation of the stainless steel particles in thermal spraying processes. These oxides are unstable in a Cl−-containing environment and act as the reactive sites for pits initiations. The present work emphasizes the role of oxidation resistance of the reinforcement on the pitting resistance of amorphous coatings and could bring some alternative recommendations to the design of amorphous composite coatings for corrosion and load-bearing applications.