N. Li, et al. Accepted for publication in Materials Science & Engineering A

http://dx.doi.org/10.1016/j.msea.2016.07.039

Abstract:

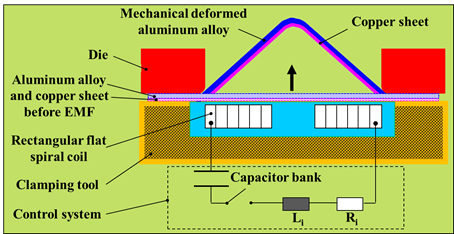

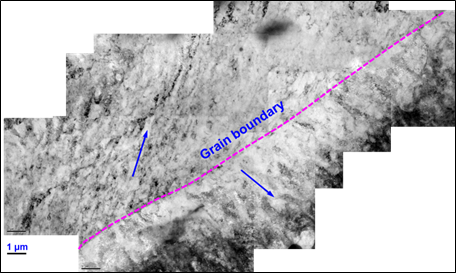

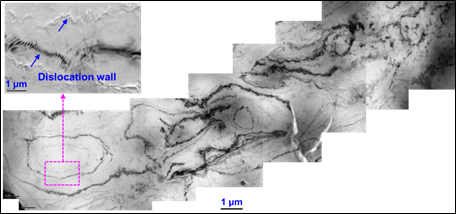

The identification of different deformation mechanisms in aluminum alloy under electromagnetic forming and mechanical high-velocity forming is a daunting task, due to the limitations in performing identical experimental conditions. Here, we present a special strategy to achieve electromagnetic and mechanical deformations with equivalent strain and strain rate. The intriguing finding is that the deformation mechanism of 5052 aluminum alloy is dominated by planar slip in mechanical deformation versus wavy slip in electromagnetic forming. The physical origin of the phenomenon is rationalized according to theoretical analysis coupled with finite-element-method simulation. The finite-element-method simulation presents planar and spatial force in the aluminum alloy during mechanical deformation and electromagnetic forming, respectively. The theoretical analysis reveals that under mechanical deformation with planar force, the destruction of short range cluster on the activate glide planes reduces the local resistance of dislocation motion and facilitates the planar slip. By contrast, the collective motion of dislocations in three dimensions caused by spatial force under electromagnetic forming facilitates the wavy slip that is represented by the dislocation cell structures. Our findings provide an effective method and fundamental understanding for unveiling various deformation mechanisms in aluminum alloy under electromagnetic and mechanical processing.