Design of Fe-based Bulk Metallic Glasses with Improved Wear Resistance

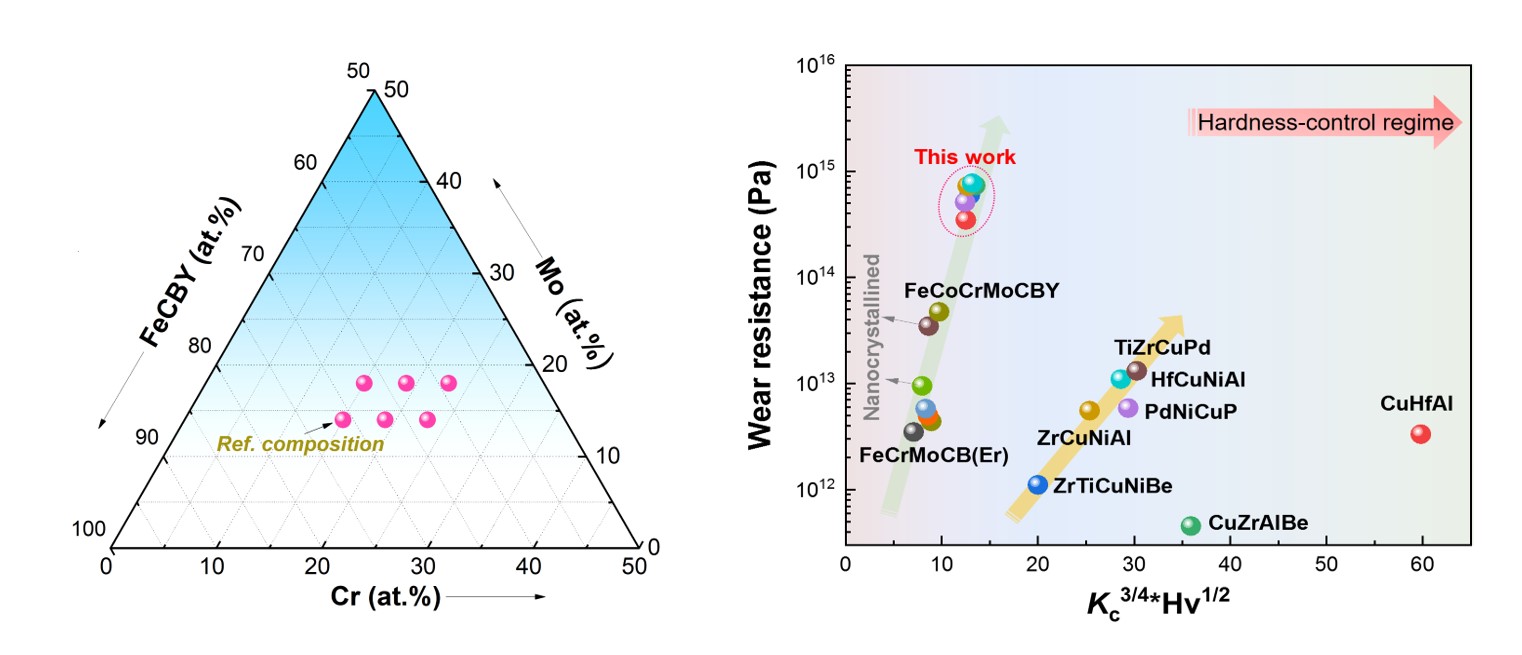

The application of bulk metallic glasses (BMGs) as advanced wear-resistant materials has remained limited despite optimistic expectations. In this work, we develop a series of novel Febased BMGs with improved wear resistance by altering the Cr and Mo contents in an Fe-Cr-MoC-B-Y glass forming system. Experimental results demonstrate that increasing Cr and Mo contents enhance the thermal stability and hardness (Hv) of the resulting BMGs without reducing their fracture toughness (Kc). The enhanced hardness is mainly attributed to the increased fraction of the stiff (Cr, Mo)-C covalent bonds in the resultant BMGs, as revealed by X-ray photoelectron spectrograph measurement. Worn surface/subsurface observations and stress field modeling reveal the activity of two kinds of wear mechanisms, i.e., hardness-controlled abrasion wear and toughness-controlled fatigue wear. We further clarify the enhanced wear performance of the Febased BMGs according to an effective indicator Kc 3/4Hv 1/2 that correlates positively with the wear resistance of the samples. The optimal Fe-based BMG sample possessed versatile properties, including a strong glass-forming ability (i.e., a minimum critical diameter of 8 mm), a high hardness of 1335 Hv, and a very low specific wear rate of ~1.3×10-6 mm3 N-1m-1 , which represents one of the most outstanding Fe-based BMGs reported thus far.