ABSTRACT

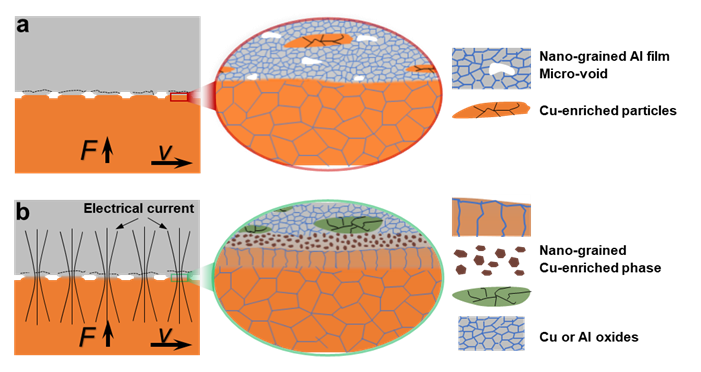

Cu/Al tribological pairs play a crucial role in maintaining the efficient operation of a wide range of engineering components. However, their durability often compromised by wear-induced damage, which involves the accumulation of material at the Cu/Al friction interface. This study investigates the intricate wear behavior of Cu/Al tribological pairs under electrical current, with a specific emphasis on material transfer events occurring at the interface. Our findings reveal that the applied electric current exerts a lubricating effect on the sliding contact friction, resulting in reduced adhesive wear. However, it concurrently exacerbates fatigue-induced delamination, abrasive wear, and electrical wear. Through detailed analysis of interface temperatures and microstructure characterizations, we demonstrate that Al deposit adhesion occurs through interfacial metal mixing and nanoscale diffusion in the presence of only mechanical friction. Conversely, at high electrical currents, interfacial melting transpires, resulting in robust adhesion facilitated by the formation of an intermetallic compound. Our findings offer valuable insights into the microscopic adhesion events occurring in Cu/Al tribological pairs and provide guidance for developing innovative coating systems aimed at reducing material deposition in Cu/Al current-carrying friction interfaces.

文章导读:

Cu/Al摩擦副因其独特的性能优势而广泛应用于电接触、轨道交通、电磁能发射等重要工程装备领域。然而,Cu/Al摩擦副服役时通常需承受大的载流,导致界面摩擦学性能急剧恶化,严重限制了其服役寿命。现有研究已经证实,载流摩擦界面的材料沉积及粘附是引发 Cu/Al 摩擦副磨损失效的关键因素。但是,针对Cu/Al 载流摩擦界面沉积层的显微结构演化规律及粘附机制,目前仍缺乏深入实验研究和理论分析,

最近,华中科技大学非晶态材料研究实验室柳林课题组(第一作者:林研;通讯作者:潘杰,柳林)系统研究了Cu/Al摩擦副的载流摩擦磨损行为,并重点关注电流对摩擦界面沉积层显微结构演化和粘附机制的影响。研究结果表明:电流对Cu/Al摩擦副的滑动摩擦有润滑作用,且摩擦系数随电流增加而逐渐下降。但是,无论是否载流,Cu合金表面均发生了大面积Al合金沉积沉积层粘附。摩擦界面温升分析及显微结构表征显示,在无载流条件下,Cu/Al摩擦副的界面温升未超过摩擦副材料的熔化温度,摩擦界面Al合金沉积层的粘附机制均为摩擦应力和摩擦热诱导的固态连接;而当承受大载流时,界面温上升已经明显高于摩擦副材料的熔化温度,摩擦界面Al合金沉积层的粘附机制为摩擦应力、摩擦热及焦耳热协同作用下的液相融化连接,且Al合金沉积层内部及其与基体的界面处均形成多种金属间化合物和金属氧化物。本工作不仅澄清了Cu/Al载流摩擦界面的沉积层显微结构演化及粘附机制,也为抑制Cu/Al载流摩擦界面粘附损伤的涂层材料体系设计提供了优化方向。

相关工作发表在期刊Engineering Failure Analysis上,研究得到了国家自然科学基金项目的资助(No. 92066202,52001075,92266103,92166103和52022100)、中国博士后基金面上项目的资助(No. 2021M701290)以及中国科学院青年创新促进会的资助(No. 2020194)。