在AlCoCrFeTi0.5高熵合金中添加Ni调控双相结构优化力学性能

第一作者:郭容 通讯作者:潘杰,柳林

Abstract

High-entropy alloys (HEAs) have attracted increasing attention as structural materials due to their excellent mechanical properties; however, most single-phase HEAs still encounter the conflict between strength and plasticity, which greatly limits their engineering applications. Here we reported the use of composition design, that is the addition of Ni element into a base alloy of AlCoCrFeTi0.5 HEA, to obtain the body-centered cubic (BCC)/face-centered cubic (FCC) dual-phase structure, for avoiding the strength-plasticity trade-off. With the Ni addition increasing from 0 to 3 mol ratio, the initial ordered BCC (B2 phase) structure first transformed to a duplex BCC (A2 + B2) structure, and then to an FCC (L12)/BCC (A2 + B2) dual-phase structure. Meanwhile, the Ni-containing HEAs displayed greatly improved mechanical properties. More specifically, dual-phase AlCoCrFeTi0.5Ni2.5 HEA showed the most promising combination of strength and plasticity with a yield strength of 1.41 GPa and compressive strain of 31.8%, as well as a fracture toughness of 64.3 MPa·m1/2. Post-deformation structural analyses of the AlCoCrFeTi0.5Ni2.5 HEA revealed that the activation of dislocations slip and stacking fault in the FCC (L12) phase, precipitation strengthening in BCC phase (B2), together with the synergic deformation between FCC and BCC phases, contribute to the desirable capability of strain hardening. Our work shows that the use of dual-phase architecture can be an effective microstructure-design strategy for developing HEAs with a favorable strength-ductility synergy.

文章导读:

高熵合金(HEAs)以其独特的原子结构特征和优异的性能(如高强度、高断裂韧性、以及优异的抗疲劳性能、抗辐照和耐磨损性能等),成为金属材料研究领域的热点。然而,大多数单相HEAs仍不可避免地存在强度-塑性间的倒置关系(面心立方FCC结构 HEA通常韧性好但强度低,而体心立方BCC结构HEA往往强度高但韧性差),这极大地限制了其作为结构材料的广泛应用。其中,在高熵合金中引入并调控双相结构,成为改善其强韧性匹配的一个重要方向。但如何有效地设计和调控双相结构以实现HEAs力学性能的优化,仍然是目前面临的一个挑战,特别是如何在脆性的BCC结构HEAs中进行结构和性能调控。

最近,华中科技大学非晶态材料研究实验室柳林课题组基于价电子浓度(VEC)理论的成分设计,通过在单相BCC结构的AlCoCrFeTi0.5 HEA中添加具有较大VEC值的Ni元素,调控双相结构并实现优异的强塑性匹配。研究结果表明:随着Ni添加量从0摩尔比增加到3摩尔比,其微观结构由初始的有序BCC结构(B2相)首先转变为双相BCC (A2 + B2)枝晶结构,然后转变为有序FCC (L12) + BCC (A2 + B2)双相枝晶结构。当Ni含量为2摩尔时,即AlCoCrFeTi0.5Ni2.5 HEA表现出最佳力学性能,其屈服强度为1.41 GPa,压缩应变为31.8%,缺口断裂韧性高达64.3 MPa·m1/2。对变形后AlCoCrFeTi0.5Ni2.5 HEA 的结构分析发现,FCC (L12) 相中大量的位错滑移和堆垛层错的激活,BCC 相中的析出强化和晶格晶格畸变,以及FCC和 BCC相间的协同变形,这有利于抑制应变局域化,从而表现出良好的加工硬化和塑性能力。本工作为开发具有良好的强度-塑性协同作用的HEAs,特别是在研究较少的BCC结构HEAs,提供了可行的微观结构设计策略。

相关工作近期发表在Materials Science & Engineering A 831 (2022) 142194上。该研究得到了国家自然科学基金(52061160483, 52061160和52022100)资助。

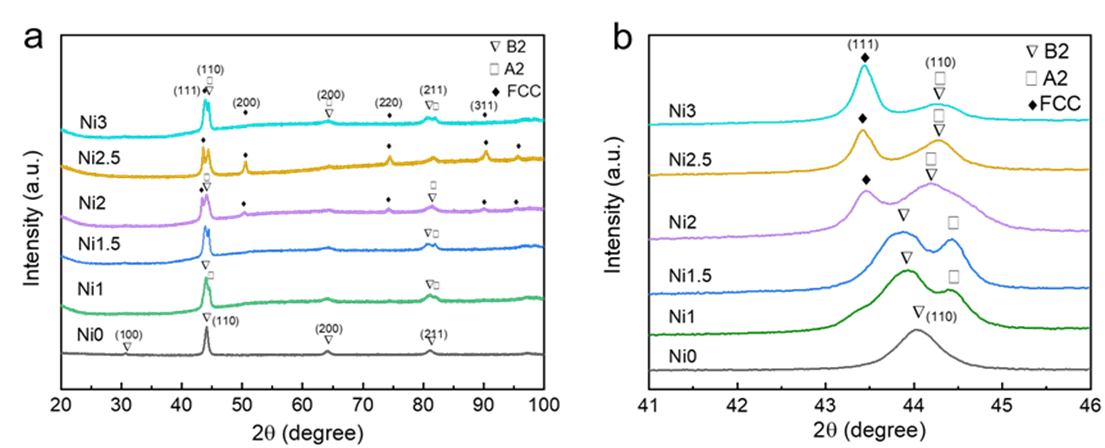

图1. 铸态AlCoCrFeTi0.5Nix (x = 0、1、1.5、2、2.5 和 3) HEAs的 XRD曲线

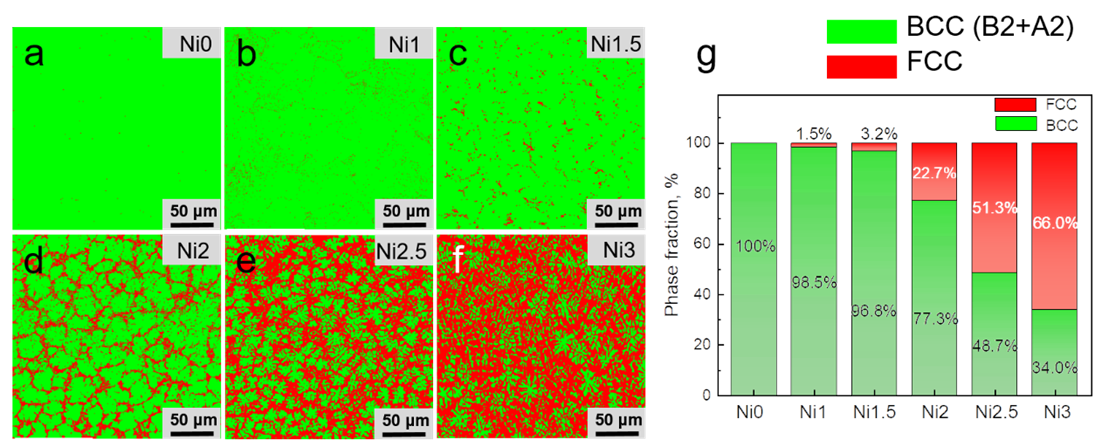

图2. (a-f) 铸态AlCoCrFeTi0.5Nix (x = 0、1、1.5、2、2.5和3) HEAs 的EBSD 图以及 (g) 各HEAs 中FCC和BCC相的体积分数

图3.铸态AlCoCrFeTi0.5Nix(x = 0、1、1.5、2、2.5和3)HEAs 的SEM微观形貌

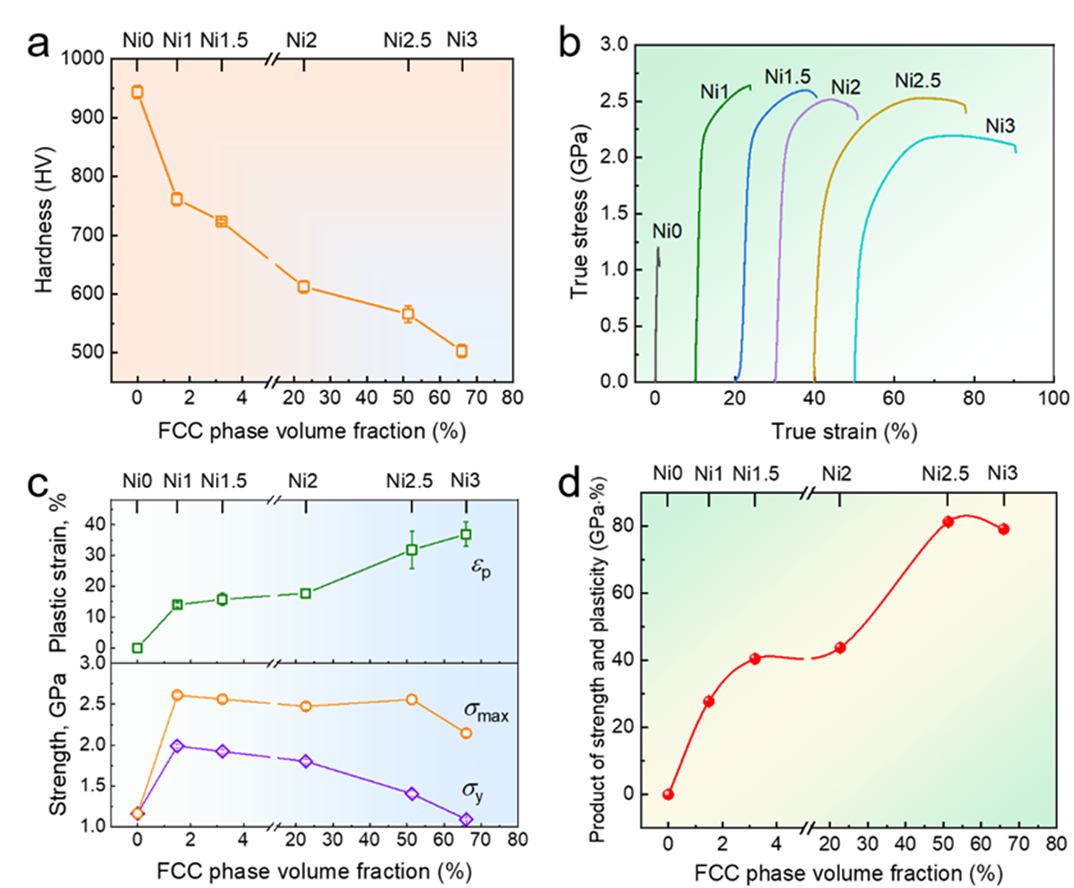

图4. (a) 铸态AlCoCrFeTi0.5Nix(x = 0、1、1.5、2、2.5 和 3)HEAs 的力学性能。(a) 显微硬度;(b)单轴压缩的真实应力-应变曲线;(c)屈服强度、最大强度和压缩应变;(d)强塑积

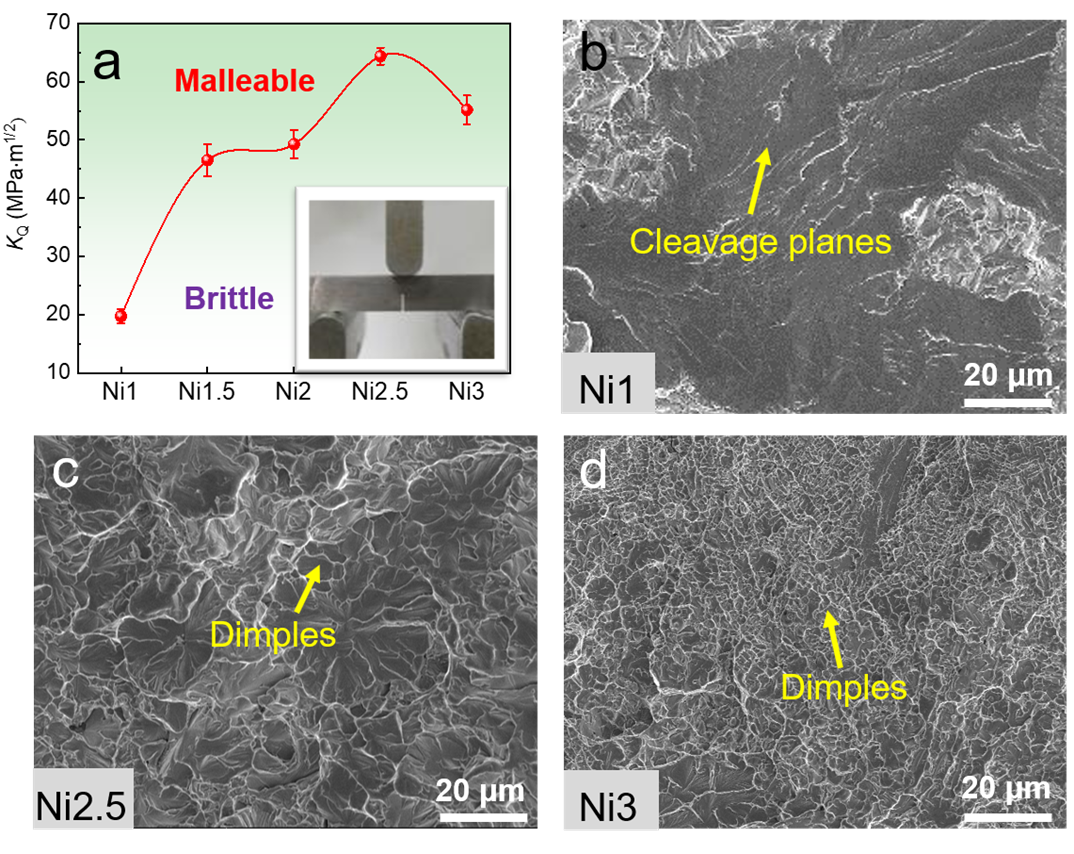

图5. (a) AlCoCrFeTi0.5Nix(x = 0、1、1.5、2、2.5 和 3)HEAs 的缺口韧性值; (b) Ni1、(c) Ni2.5 和 (d) Ni3 HEAs 在缺口韧性测试后的断口形貌

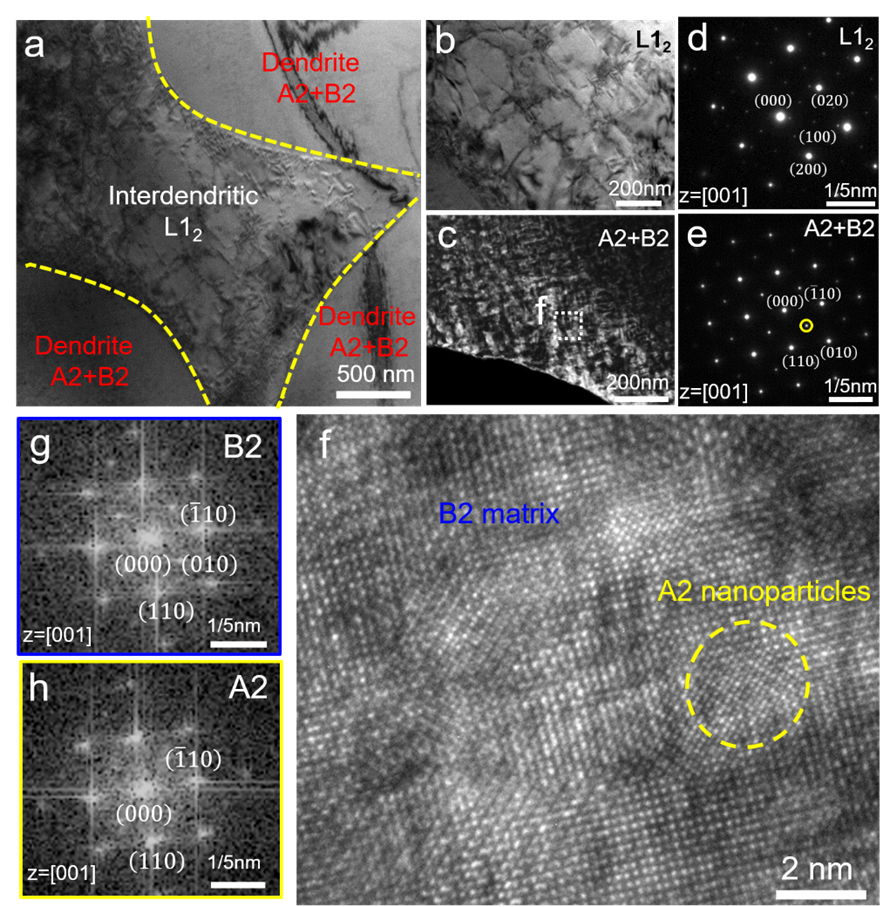

图6. 变形前Ni2.5 HEA 的TEM形貌

图7. 变形前Ni2.5 HEA 的STEM-HAADF 图像以及 中 (a) 枝晶间区域和 (b) 枝晶区域的相应元素分布

图8. Ni2.5 HEA 在 25% 压缩应变后的 TEM 形貌

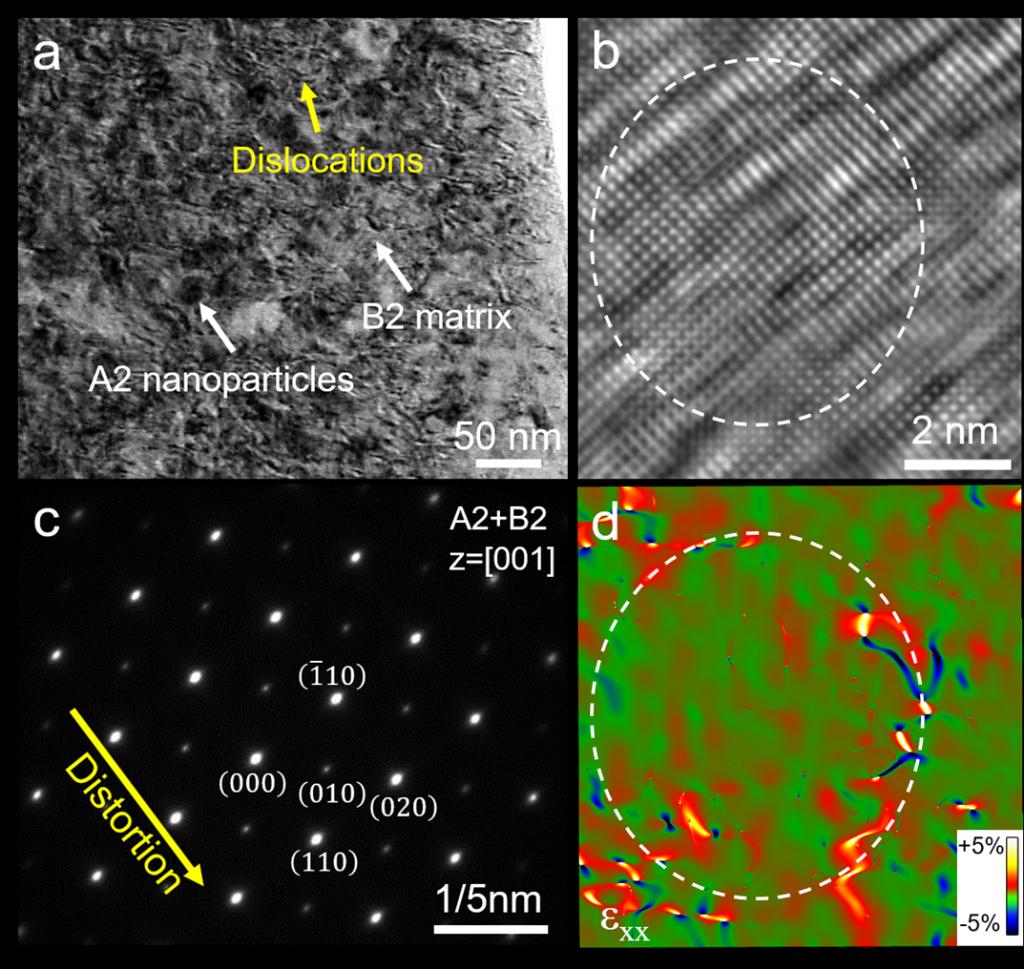

图9. Ni2.5 HEA压缩变形后BCC区域的TEM 图像