Materials Science & Engineering A:梯度结构Ni-P合金涂层的界面结合性能研究

第一作者:林研 通讯作者:潘杰,柳林

ABSTRACT

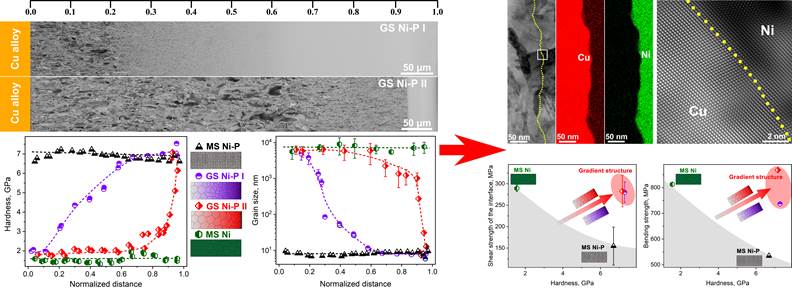

Hard metallic coatings can provide exceptional protection for industrial settings; however, they usually have a uniform microstructure and suffer from poor adhesion with substrates because of stress/strain incompatibility induced by the sharp interface. Here, a gradient structure that transitions from coarse-grained Ni to nanocrystalline/amorphous Ni–P alloy has been designed to improve the adhesion performance of the electrodeposited Ni–P coatings. Based on two measures of adhesion performance, a high interface shear strength of ~282.6 MPa and high bending strength of ~868.4 MPa have been determined for the gradient-structured Ni–P coatings on the CuCrZr alloy substrate, which are increased, respectively, by ~90% and ~60% from those of the conventional monolithic-structured Ni–P coating. Post-mortem fractographic analysis reveals that introducing the gradient structure accommodates plastic deformation of the coating and provides exceptional crack arrest capability, contributing to the enhancement of adhesion performances under both shearing and bending. The present work not only reveals how the adhesion performance can be significantly improved in gradient-structured Ni–P coatings, but also provides a promising methodology for manufacturing novel GS metallic coatings with a combination of excellent surface functions and strong interface adhesion.

文章导读:

金属涂层能给严苛工况下的机器零部件提供有效的防护,延长其服役寿命。然而传统高硬度金属涂层通常是均质纳米结构,使均质涂层与基体之间存在难以避免的应力/应变不相容性,导致高硬金属涂层在界面结合性能提升方面一直存在瓶颈。近年来构筑梯度结构已成为突破金属材料综合性能的有效途径之一。其中在金属涂层中引入梯度结构不仅能保持涂层表面优异的性能,而且有利于消除界面两侧力学性质的差异,受到了研究者的广泛关注。但是,由于制备方法的限制,目前有关梯度结构如何影响梯度涂层界面结合性能仍缺乏深入研究。

最近,华中科技大学非晶态材料研究实验室柳林课题组基于直流电沉积方法,通过连续调控电沉积过程中的电流密度和添加剂浓度,在Ni-P合金涂层中制备出了晶粒尺寸和化学成分复合的双重梯度结构。研究结果表明:梯度结构Ni-P合金涂层的晶粒尺寸由6 μm逐渐细化至10 nm,P含量从0增加至~9 at.%,相应的涂层硬度由界面侧的~1.8 GPa逐渐增大至表面侧的~7.2 GPa。涂层剪切和弯曲测试结果显示梯度结构Ni-P涂层与CuCrZr合金基体间的界面结合强度和弯曲强度高达~280 MPa和870 MPa,相比于传统均质纳米晶Ni-P涂层分别提升了~80%和~60%。通过引入梯度结构,利用梯度结构协调界面附近的变形和抑制涂层中的裂纹萌生及扩展,可以实现Ni-P合金涂层高界面结合强度和高表面硬度的良好结合。同时,通过调整涂层的梯度结构分布形式,可进一步提高梯度涂层的弯曲强度。本工作不仅为制备兼具高表面硬度和强界面结合的梯度结构金属涂层提供了可行的微观结构设计策略,也拓展了梯度结构金属涂层的工程应用前景。

相关工作发表在期刊Materials Science & Engineering A上,研究得到了国家自然科学基金项目的资助(No. 92066202,52001075和52022100)以及中国博士后基金面上项目的资助(No. 2021M701290)。